Laboratory Muffle Furnace

Product Details:

- Feature strong and durable

- Size diff sizes available

- Color colour coated

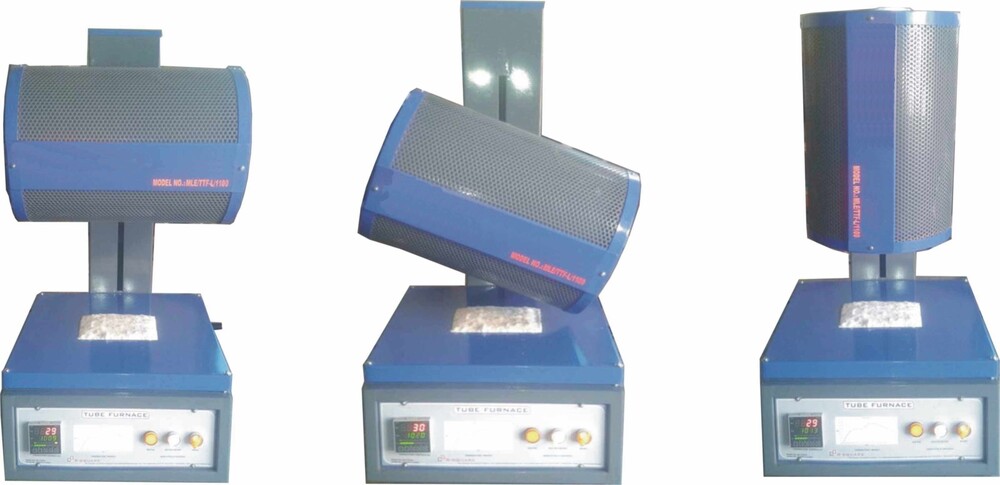

- Product Type Split Tube Furnaces

- Condition New

- Type Split Tube Furnaces

- Application industrial

- Click to View more

Laboratory Muffle Furnace Price And Quantity

- 1 Piece

- 20000 INR/Piece

Laboratory Muffle Furnace Product Specifications

- New

- strong and durable

- Split Tube Furnaces

- diff sizes available

- industrial

- Split Tube Furnaces

- colour coated

Laboratory Muffle Furnace Trade Information

- 50 Piece Per Month

- Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India West India Assam Rajasthan Himachal Pradesh Dadra and Nagar Haveli Andhra Pradesh Haryana Maharashtra Lakshadweep Madhya Pradesh North India West Bengal Arunachal Pradesh Daman and Diu Central India Goa Uttar Pradesh Kerala Chhattisgarh East India Chandigarh Bihar Telangana Uttarakhand Odisha Tripura Tamil Nadu Delhi Jammu and Kashmir Meghalaya Punjab South India Sikkim Nagaland Gujarat Pondicherry Mizoram Jharkhand Karnataka Andaman and Nicobar Islands Manipur

Product Description

A laboratory muffle furnace is a countertop oven used for subjecting materials to high temperatures in a controlled environment. Unlike an oven that uses an open flame for heating, a muffle furnace utilizes electrical heating elements and has an insulated chamber to isolate the test materials from the combustion byproducts and maintain consistent temperaturesHere are some common applications of laboratory muffle furnaces:

- Ash content determination: This process involves burning a material completely at high temperatures to determine the amount of incombustible residue remaining.

- Loss on ignition (LOI): Similar to ash content determination, LOI test measures the mass lost by a sample upon heating. This can be used to determine the amount of moisture, volatile components, or organic matter present in a material.

- Heat treatment: Muffle furnaces are used for various heat treatment processes, such as annealing, hardening, and tempering of metals.

- Material testing: Muffle furnaces can be used to test the thermal stability of materials or observe their behavior at high temperatures.

- Decomposing materials: Certain materials decompose at high temperatures, and muffle furnaces can be used in controlled experiments to study this process.

Muffle furnaces come in various sizes and with different maximum temperature ranges. They typically have features like:

- Rugged construction for withstanding high temperatures

- Programmable temperature controllers for setting and maintaining desired temperatures

- Overheat protection for safety

- Door safety switch that cuts off power when the door is opened

When working with a muffle furnace, it's important to follow safety protocols, such as wearing appropriate personal protective equipment (PPE) and using crucible tongs to handle hot materials

Here's a sample FAQ (Frequently Asked Questions) for a laboratory muffle furnace:

1. What is a muffle furnace?A muffle furnace is a type of high-temperature laboratory oven designed for heat treatment processes such as annealing, sintering, calcining, and heat sterilization. It features a heating chamber with insulation and a separate muffle (or retort) to contain the sample or material being heated.

2. What are the applications of a muffle furnace?Muffle furnaces are used in various industries and research fields for tasks such as ashing, drying, decomposition, and thermal testing of materials, ceramics, metals, polymers, and more. They are essential for conducting controlled heating experiments and processing samples under specific temperature conditions.

3. How does a muffle furnace work?A muffle furnace consists of a heating element, insulation, temperature controls, and a separate muffle or chamber where the sample is placed. The heating element generates heat, which is circulated within the chamber to achieve and maintain the desired temperature. The muffle ensures uniform heating of the sample while protecting it from direct contact with the heating elements.

4. What types of materials can be processed in a muffle furnace?Muffle furnaces can handle a wide range of materials, including powders, pellets, metals, ceramics, glass, and more. They are commonly used for heat treatment processes such as drying, annealing, sterilization, and thermal decomposition of organic and inorganic samples.

5. What are the temperature capabilities of a muffle furnace?Muffle furnaces can reach temperatures ranging from a few hundred degrees Celsius to over a thousand degrees Celsius, depending on the model and specifications. Some high-temperature models can even reach temperatures exceeding 1,500C or higher for specialized applications.

6. How do I choose the right muffle furnace for my needs?Consider factors such as temperature range, heating uniformity, chamber size, insulation quality, control precision, safety features, and any specific heating requirements for your applications. Consulting with a reputable supplier or manufacturer can help you select the best muffle furnace for your laboratory or research facility.

7. What safety precautions should be followed when using a muffle furnace?Safety precautions for operating a muffle furnace include wearing appropriate personal protective equipment (PPE), ensuring proper ventilation, avoiding contact with hot surfaces, and following manufacturer's instructions for safe operation and maintenance. It's also important to be aware of fire hazards and potential chemical reactions when heating certain materials.

8. Can a muffle furnace be used for controlled atmosphere or inert gas applications?Yes, some muffle furnaces offer optional accessories or configurations for controlled atmosphere or inert gas environments. These features allow for processes such as sintering under protective atmospheres or conducting reactions in oxygen-free environments.

9. How do I clean and maintain a muffle furnace?Regular maintenance and cleaning are essential to ensure the performance and longevity of a muffle furnace. This may include removing ash or residue from the muffle, inspecting heating elements and thermocouples, calibrating temperature controls, and replacing worn-out parts as needed.

10. Where can I purchase or rent a muffle furnace?Muffle furnaces are available from laboratory equipment suppliers, manufacturers, and distributors. You can also inquire about rental options if you have short-term testing needs or want to evaluate a specific model before purchasing

Other Products in 'Muffle Furnace' category

|

SHIVANI LAB EQUIPMENT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free