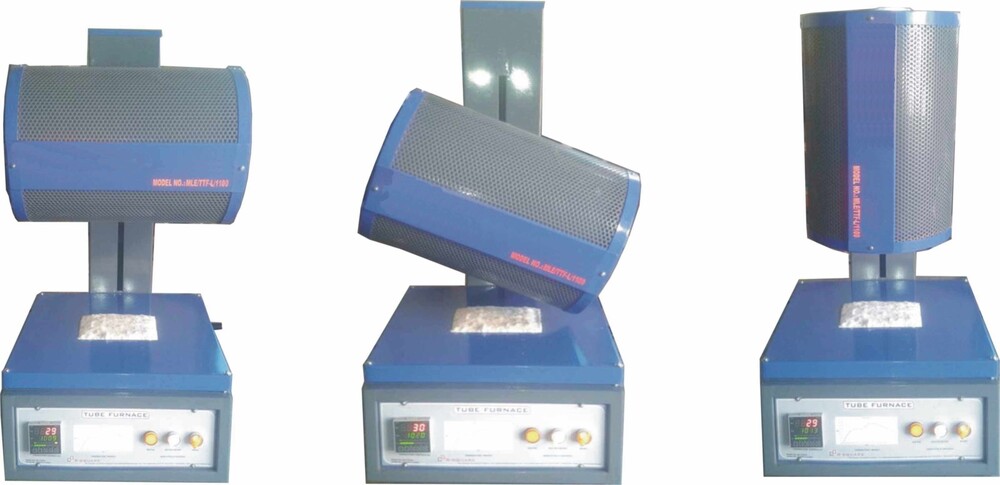

Tube Furnace

100000 INR/Number

Product Details:

- Height Custom

- Size Custom

- Product Type Muffle furnace

- Usage Lab testing

- Weight Custom

- Width Custom

- Color Custom

- Click to View more

X

Tube Furnace Price And Quantity

- 01 Number

- 100000 INR/Number

- 100000.00 - 300000.00 INR/Number

Tube Furnace Product Specifications

- New

- Custom

- NA

- Custom

- Custom

- custom

- Custom

- Custom

- Lab testing

- Muffle furnace

- Custom

- Materials Research: Ideal for synthesizing new materials and studying their properties under controlled thermal conditions. Ceramics: Used for firing and sintering ceramic materials, providing precise temperature control for optimal results. Metallurgy: Essential for heat treatment processes, including annealing, tempering, and stress relieving of metals and alloys. Thermal Testing: Suitable for testing the thermal properties and behaviors of various materials under high temperatures. Academic and Industrial Research: Widely used in research laboratories and industrial R&D centers for various thermal processing applications.

- 230 Volt (v)

Tube Furnace Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 10 Number Per Month

- Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Key Components

- Heating Element: Typically made from materials like Kanthal (iron-chromium-aluminum alloy) or silicon carbide, which can sustain high temperatures.

- Tube: The tube, where the sample or material to be heated is placed, can be made of quartz, alumina, or other materials resistant to high temperatures and chemical reactions.

- Insulation: High-temperature insulation surrounds the heating elements to ensure minimal heat loss and efficient energy use.

- Temperature Controller: A precise temperature control system, often a digital controller, ensures accurate temperature settings and stability.

- Gas Flow System (Optional): For certain applications, gases (like nitrogen, argon, or forming gas) are introduced into the tube to create specific atmospheric conditions.

Types of Tube Furnaces

- Single Zone: Has one heating zone, providing uniform temperature distribution within that zone.

- Multi-Zone: Features multiple heating zones, allowing for gradient temperatures along the length of the tube.

- Split Tube: The furnace can be opened into two halves, making it easier to insert and remove samples.

- Rotary Tube: The tube can rotate, which is useful for mixing samples or ensuring uniform heat exposure.

Applications

- Materials Research: Sintering, annealing, and calcining materials.

- Thermal Analysis: Conducting experiments like thermal gravimetric analysis (TGA) and differential thermal analysis (DTA).

- Chemical Synthesis: Producing materials at high temperatures, such as catalysts and ceramics.

- Heat Treatment: Treating metals and alloys to alter their properties.

- Gas Phase Reactions: Conducting reactions that require a controlled atmosphere.

Advantages

- High Temperature Capability: Can reach temperatures up to 1200C or higher, depending on the model and materials used.

- Uniform Heating: Ensures even heat distribution, which is crucial for precise material processing.

- Versatility: Suitable for a wide range of applications due to various customizable options (e.g., gas flow systems, multiple zones).

- Controlled Environment: Can maintain a controlled atmosphere to protect materials from oxidation or contamination.

Safety Considerations

- Temperature Control: Use accurate and reliable temperature controllers to prevent overheating.

- Material Compatibility: Ensure that the tube and any inserts are compatible with the temperatures and chemicals used.

- Ventilation: Proper ventilation is essential to avoid buildup of harmful gases.

- Personal Protective Equipment (PPE): Use appropriate PPE, such as heat-resistant gloves and eye protection, when handling the furnace.

Tube furnaces are essential tools in scientific research and industrial processes, offering precise temperature control and a versatile environment for a wide range of high-temperature applications.

Enter Buying Requirement Details

Other Products in 'Muffle Furnace' category

|

SHIVANI LAB EQUIPMENT

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS